Carburetors use a power-enriching circuit (also called starter circuit by some companies) which operates at engine start. Design and operation will vary between models.

The most basic circuit features a second valve behind the carburetor, near the air filter. This valve cuts most of the air intake in order to enrich the air-fuel mixture and allow easier starts.

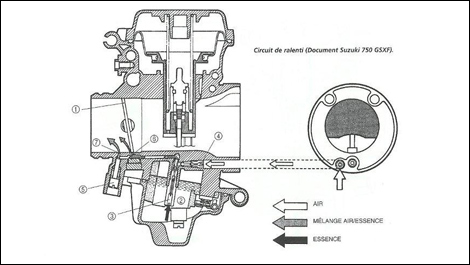

Another system is found on the engine's side. This circuit has no valve; instead, it uses a small diver with a seal on the contact surface. Its job is to let air enter through a duct -- with the opening on the same side as the air filter case. (The slide is completely shut, in idle mode). Upon starting, the engine creates a vacuum between the slide and the combustion chamber. Once the circuit is open, fuel is sucked in the float chamber through the needle valve. The air-fuel mixture gets richer and there's no need to hit the throttle lever. You have to wait for the engine to warm up, which only takes a minute or two. As soon as the engine speed becomes stable, lower the choke lever. (In some cases, you might have to hit the throttle two or three times before pushing the engine start button -- or you can use the manual starter.)

|

The secondary circuit uses a small pump inside the float chamber of the carburetor. The pump is controlled by a lever mechanism connected to the throttle cable. Therefore, it also improves engine response during upshifts.

This small mechanism consists of a diver, a membrane and a sprinkler which controls fuel flow. Flooding the engine at the start is pretty easy. If that happens, don't hit the throttle lever; let it slightly open and restart the engine. The excess (non-burnt) fuel will be expelled. If the engine does not start again, it might be the result of a flooded spark plug. Take it out and wipe it dry with a sponge paper.

Performing basic carburetor adjustments on a single-cylinder engine is fairly easy. However, with twin-cylinders, you have to be a little more careful and delicate. The first step is to pre-adjust the mixture screw or air screw, depending on the type of carburetor. Always refer to the repair and maintenance manual. You should find a chart with all the technical specifications for every motorcycle and carburetor model. Manufacturers make changes every year and, obviously, the recommended adjustments also change.

Using a screwdriver, turn the screw clockwise with minimal effort (two fingers should be enough). Go back counter-clockwise and count the number of turns recommended by the manufacturer. Then, start the engine and let it warm up. Slowly turn the screw counter-clockwise and check if you can hear the engine rev up. Stop when you notice that the sound is changing. Over time, your ears will become more familiar with the engine sound. When properly set, hit the throttle a couple of times; the engine must respond unhesitatingly.

Remember to check for any signs of leak where the carburetor is mounted. Also, the air filter should be cleaned up or replaced before any carburetor adjustment is made.

This wraps up our feature on engine carburetion.

Photo Credit : Henri Lebarbé