Building the safest bike on the market involved the development of several highly sophisticated electronic features, then making them work together (“Integration” in software terms) in a coherent fashion.

The BMW developers and testers created four different riding modes (Rain, Sport, Race and Slick), and fine tuned the systems to adapt them to the performance and safety levels required for each mode.

Our first track ride on the S1000RR allowed us to validate these features in three of the four modes, as I personally left the “Slick” Mode to racers. Describing and riding the bike made for a separate article.

Describing all the electronics on the S1000RR and how they work is involved enough to justify this separate paper, together with cross references between the ride report and this document, to facilitate reading and comprehension.

Here are descriptions of the various systems at work to optimize performance and safety, and the benefits thereof. The various on-board computers will be referred to collectively as the Engine Control Unit (ECU) to simplify the text.

Variable length intake trumpets

Low frequency sounds and resonance are associated with long conduits, while high frequencies are associated with shorter ones. For example, a trumpet (High notes) is shorter than a slide trombone (Low notes).

The intake side of a four stroke engine takes advantage of the pulses, created by the opening and closing of the intake valves, to create synchronized waves of incoming air that are used to “supercharge” the cylinder with air on the intake stroke. A long intake trumpet does this nicely under 6000rpm (Good for torque), while a shorter trumpet works better from there to maximum rpm (Good for power).

This length change is accomplished by installing long two-piece intake trumpets and programming the Engine Control Unit (ECU) to separate the extra length when the rpm goes over a certain limit.

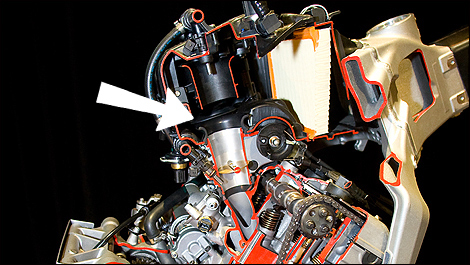

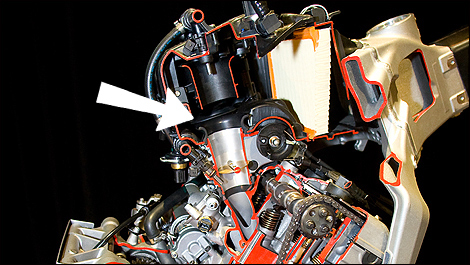

|

| The arrow shows the lower, fixed short intake stack. The extension is poised above it, waiting for the ECU to tell it to go down and mate with the base, to favour low rpm flow, and thus torque. |

This feature provides for a fatter and more constant torque output, over a longer rev range. Torque also remains higher at very low and very high rpm, to produce more power across the whole rev range.

Throttle by Wire

The throttle wire coming from the twist grip actuates a sensor that sends the signal from your wrist to the ECU for processing. This signal is then combined with other sensor inputs regarding the engine, temperatures, lateral and longitudinal lean angles, and wheel speed sensors.

Based on all this information, the ECU then activates the intake butterflies and sets timing and fuel injection flow and timing. It does not stop there, as it also manages several other functions. Here are a few of them.

Power setting – The ECU controls power output, producing 153hp in Rain Mode and 193 in the other three modes (200 at 100kph when ram air takes effect), thereby adapting power to the riding conditions and rider preference.

Torque Smoothing - Torque flows from an engine in a continuous series of small flat spots and sudden rises that can disturb the rear contact patch and decrease grip. The ECU knows what happens at what rpm and continuously adjusts the throttle butterflies to effectively smooth out the torque curve and let torque flow out to the clutch in one nice continuous flow.

Throttle dampening – In Rain and Sport modes, the ECU increases throttle opening more slowly than in the other modes, reducing a “Snap open” motion from the rider by a safer 5% to prevent loss of grip at the rear.

Race ABS

The ABS uses wheel-speed sensors to reduce braking effort to that wheel when it senses a set level of slippage. The sensitivity of the system varies according to the active Mode, permitting no slippage in Race mode and more and more in the other three.

|

| The ring with holes senses rotational speed of the front wheel, that is the used as input to the DTC and ABS systems. You can also see the on-piece Brembo caliper, and the adjustment screw for the fork damping, with the 1 to 10 numerals on the red ring to show the setting. |

Linked brakes – The ABS will also add some rear braking when it senses very hard braking at the front.

Anti Stoppie – When sensors indicate that the rear wheel is off the ground, the system will reduce front braking slightly to let the rear touch the ground.

In all cases, the ABS optimizes traction according to the Mode settings, making for a safer ride under all conditions.

Dynamic Traction Control (DTC)

When wheel-speed sensors detect a difference between front and rear wheels, with the brakes not applied and the engine pulling, the ECU assumes that the rear tire is slipping. The DTC then reduces fuel and ignition, in that order, to reduce power until slippage drops to an acceptable level for the active Mode.

Wheelie Control - In Rain and Sport modes, lean angle sensors and the ABS sensors can tell the ECU that the front wheel is in the air (it slows down relative to the rear wheel and the brakes are not applied). After a set number of seconds, or according to set maximum wheelie angles for each Mode, the ECU reduces the throttle slightly to bring the wheel back on the ground.

The ECU allows such wheelies up to 29 degrees of lateral lean, which makes for spectacular wheelies (Up to 33 degrees nose-up attitude) when coming out of corners sideways – great for pictures!

Power Freeze – The ECU senses lean angle and limits power if the angle is greater than a limit set for each Mode. As the bike returns toward the vertical, the ECU feeds the power back gradually, according to the throttle opening, the limits of the active Mode, and the input from other sensors regarding slippage or wheelies.

The rider can turn off the DTC as wells as the ABS at any time.

Slipper Clutch

The S1000RR clutch only allows power to go from the engine to the gearbox. When the throttle is shut, the bike pushes against the engine braking produced by the motor, the clutch slips and absorbs some of the energy coming from the rear wheel. This slippage is mechanical on the S1000RR, so that this slippage effort is set to work well at higher rpm, i.e. when engine braking (erroneously referred to as “Compression” is at a maximum.

A slipper clutch also contributes greatly to rider safety on the street, by preventing rear wheel lockup from engine braking when the rear wheel goes over a slippery surface, such as oil, sand or standing water.

Shift Assist

When the rider’s boot moves the shift lever a few millimetres as part of an upshift, fuel and ignition are cut ease the engagement of the gears (Actually dog clutches). This means full throttle gear upshifts and no significant interruption in acceleration.

Downshifts still require the use of the clutch, and blipping the throttle to ease the life of the slipper clutch and help it prevent blocking or skipping of the rear wheel from engine braking.

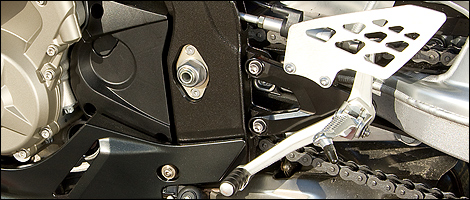

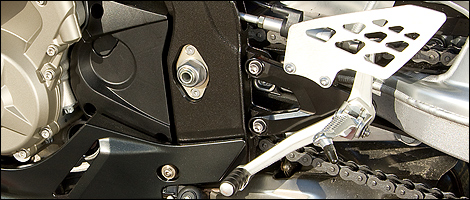

|

| You can see the cover of the swingarm pivot axle, which can be raised or lowered to compensate for changes in ride height and to optimize weight transfer on corner exits. |

How it all works together

The four Mode setting allow a rider to select a set of variables according to riding conditions, preferences and skill level (aka bravery).

| Mode |

Power/ Throttle Response

|

DTC/ABS

Settings |

Power Freeze

Lean Angle

|

Wheelie Control |

| Rain |

153 hp, 5%

throttle

dampening |

High DTC

intervention

Anti rear wheel lift ABS |

38º |

5 sec before throttle is reduced |

| Sport |

193hp, 5%

throttle

dampening |

Medium DTC

Anti rear wheel lift ABS |

45º |

5 sec before throttle is reduced |

| Race |

193hp, no

throttle

dampening |

Light DTC |

48º |

None |

| Slick

|

193hp, no

throttle

dampening |

Very Light or no DTC |

53º |

None |

The ABS and DTC can be disabled independently by the rider at any time.

The various limits in angles, dampening and other variable were arrived at during exhaustive testing, and worked well when I rode the bike.

BMW can always reset some of these values over time, as knowledge about the bike and how it works grows with the number of bikes on the road or track.

Computational Fluid Dynamics (CFD) simulation

Every major manufacturer and race teams in F1, NASCAR and Endurance racing use CFD simulation to accelerate the development and optimisation of the vehicles.

In the case of the S1000RR, BMW used CFD to optimise the circulation of water, oil, air and fuel in the engine, as well as the air around the fairing. In this last example, CFD helped with the evacuation of heat, protection from the elements, and reduction of turbulence.