We will now talk about the design of exhaust systems. Back when motorcycles were invented, there were no construction standards or noise limits. Oh how the times have changed! It has never been more complex and demanding to design an exhaust system that delivers not only a high performance but also an appropriate, sweet-sounding exhaust note.

|

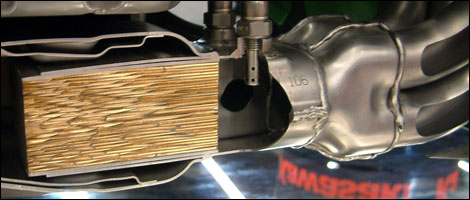

| Cutaway of an exhaust line |

Modern technological advancements in mechanics and electronics are amazing. Engineers and designers have to be extremely creative and competitive; after all, their goal is to create motorcycles that are increasingly faster and more powerful while burning less fuel. We see more and more lightweight materials and sophisticated components. Quite frankly, designing a modern exhaust system has virtually become an art form.

At first, companies built exhaust systems from a piece of coiled-up sheet metal or from a pipe section. Today, computers do all the work. Designers use special software to draw and configure the various parts of the system, with the help of actual and virtual simulations on a motorcycle.

Computerized modelling provides manufacturers a starting point for the development process. Once the project is approved, engineers begin working on the system and putting it to the test. All the data is recorded on a computer and simulations are performed to gauge every parameter of the system, such as air temperature and pressure. For instance, huge fans are used to feed air through the intake manifold and possibly inside the dynamic air system. After completion of these tests, graphics are compared and lines are modified (inner diameter, exhaust length, etc.) to address "power gaps", among others.

Whether it's a 2- or 4-stroke engine, the exhaust system has to deliver superior performance. To do so, engineers must factor in the fluid column, which consists of the air filter case, the diameter and length of the intake manifold ducts and the carburetor body. Then, depending on the engine type (2- or 4-stroke), they calculate the exact effective displacement. Also taken into account are the inner valve channels as well as the shape of the piston crown/cylinder head and exhaust manifold. As for the exhaust system itself, engineers have to consider the diameter, curve and length of the pipes connecting to the muffler or catalytic converter. The muffler will be calibrated to ensure full power and the appropriate noise level. The materials being used are also important: the thickness and reverberating properties of the sheet metal, for instance, will influence the sound waves produced by the combustions inside the engine. With most manufacturers, the pipe leading out of the exhaust manifold of the cylinder head features a two-layer tubular assembly that extends over a predetermined length to mitigate the noise and heat produced by the combustions.

|

| Cutaway of a catalytic converter |